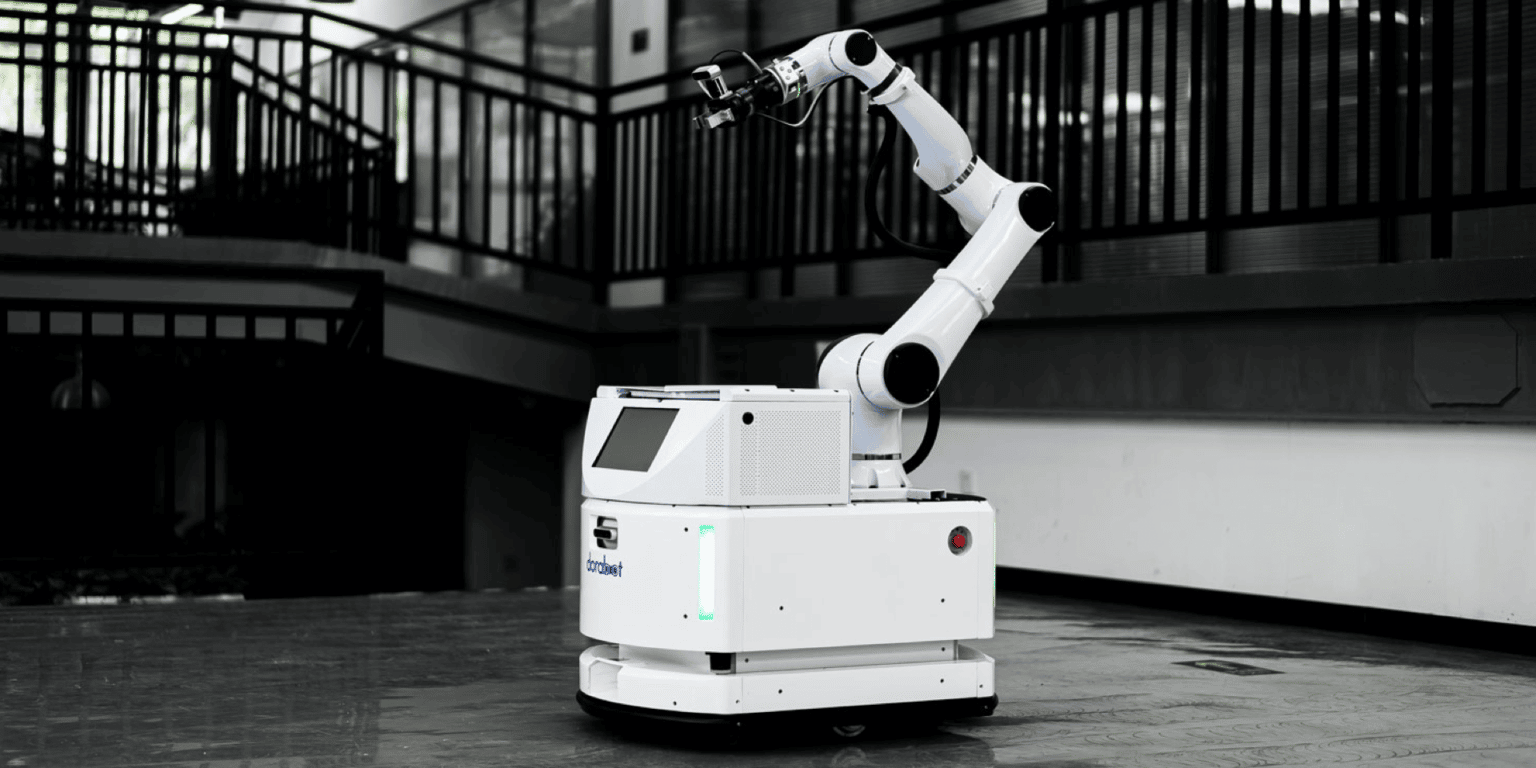

Mobile manipulator robot monitors environment

Printed Circuit Board Company

High Tech Co Embraces Robotics

Enviromental Monitoring

Background

A well-known electronic circuit technology and solution integrator in China had concerns about monitoring the work environment, to ensure safe conditions.

The company produces printed circuit boards (PCB) and conducts surface-mount technology (SMT) to place circuits directly onto the boards. The process, and the health of the company’s operators are dependent on a number of environmental factors, ranging from humidity and temperature to gas-related air quality.

Monitoring the environment includes a number of manual processes that can, and very likely should, be conducted by a robot.

Challenges

It is necessary to monitor the workshop environment temperature, humidity, special gas content and other parameters at all times

Materials need to be checked across floors in time, which is difficult to operate

Sampling point and machine tool quantity is large, so it is easy to make mistakes with manual operation

Need for regular broadcast and automatic alarm function

Solution

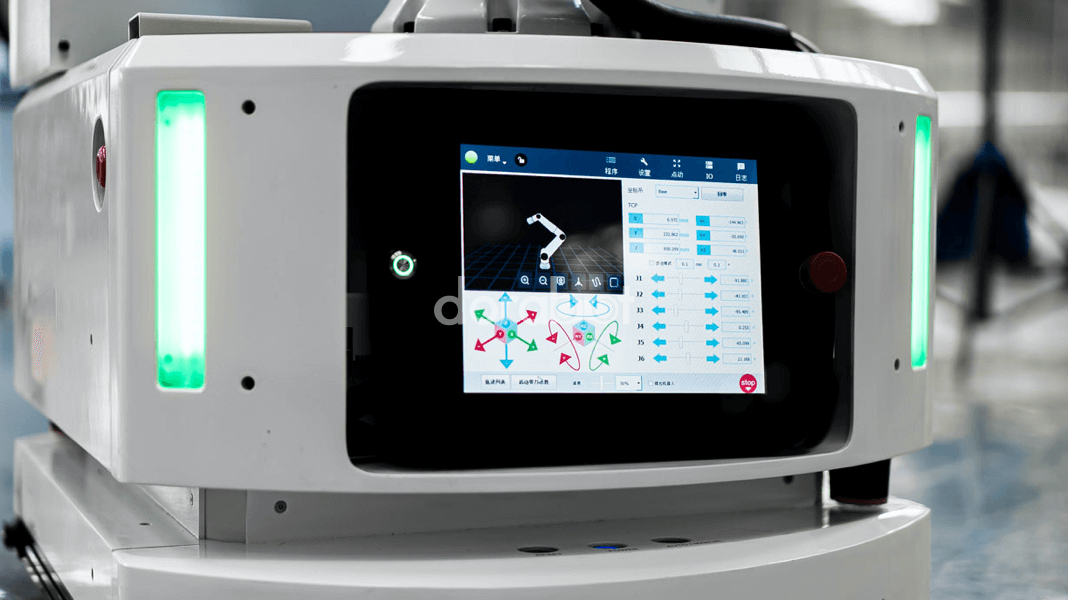

·DoraMOMA (compound mobile cooperative robot) was used for workshop inspection and material handling

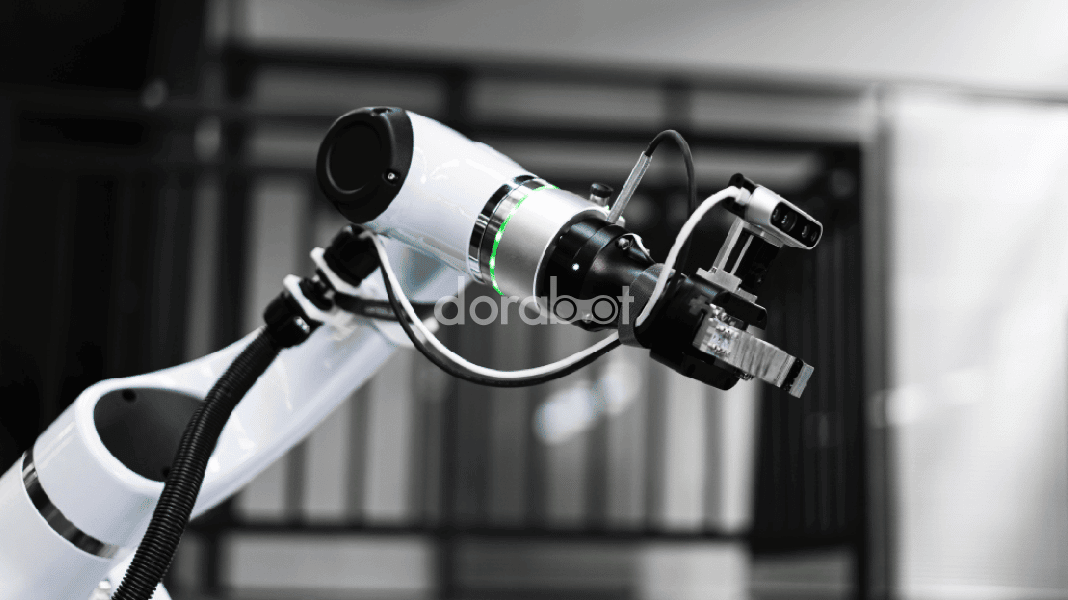

·Customized special gripper with intelligent camera, can accurately identify, grasp and place materials

·Equipped with a variety of environmental parameters sensor, detect environmental changes at any time

·Automatic ladder, complete the task across floors

·Calls are made through the software interface or web client to trigger tasks

·Support remote voice intercom, background through the robot and the scene dialogue, and can get pictures through the camera

·The perfect visual management system can realize tasks delivery, operation process monitoring, map sampling point update, inspection route management, equipment management and intelligent broadcasting and other functions

Technical Features

High precision laser SLAM navigation, real-time positioning, intelligent obstacle avoidance

The manipulator control algorithm based on deep learning ensures accurate and stable grasping of raw material tray

The number of machines can be increased to support multi-machine scheduling

Intelligent path planning, according to the command to move to the designated location

Customer Benefits

Reduce manual operation in workshop, which ultimately reduces risk of injury

Automatic and intelligent operation process ensures work efficiency

Intelligent broadcasting helps improve the safety factor of the operation

Real-time system docking, to achieve high efficiency, safety and data traceability of the production process